“The Ttarp machine is the best equipment we have purchased in 30 years, and I am including everything from copiers to the cars I have bought.”

Owner/President | Sample Carpet Converter | Georgia

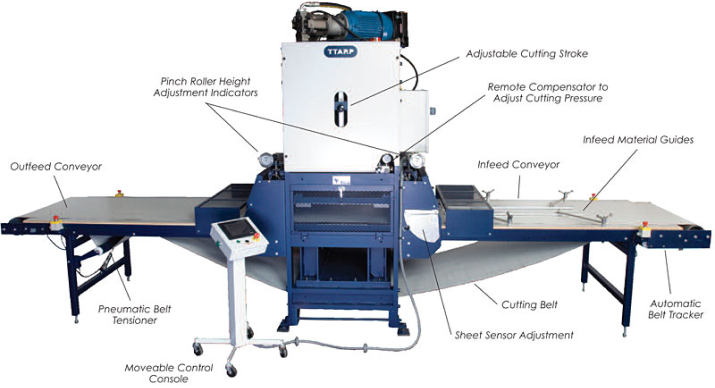

Standard Options for Die Cutting Presses

Ttarp die cutting presses are available with various performance features shown in the photo above as well as options and accessories to provide you with fabricating equipment designed to meet your needs. Contact us if you have a specific challenge or application requirements.

Download Specification Sheet:

OPTION A – AIR CLEAN OUT SYSTEM

- 2 HP blower draws waste punch plugs into a bag or trash can inside the vacuum box

- Dies are mounted on a die plate with it’s corresponding bolster plate. Plugs travel thru punch and bolster plate into an air corridor and then into the vacuum box

- Fits all Ttarp Press Models

- Includes: die plate with mounting rails, stop blocks, flexible hose 4” neck connection, 6’ flexible hose, vacuum box has 12’ power cord to press control panel, operates at press voltage, plastic bucket collection

- Not included: die and corresponding bolster plate

- Contact us to discuss application details regarding effective materials and waste plug dimensions

Option B – Heavy Duty Roll Feed

- 3” core air bars, 48” diameter max, and 300 lb max.

- Manual friction brakes prevent free wheeling of roll

- Swivel, 4 heavy duty casters, 2 swivel – locking type

OPTION C1 & C2 10ft Long Infeed and Outfeed Table

- Standard 7’ infeed or outfeed is replaced with a 10’ length table

- Provides room for additional personnel for picking off conveyor in high speed – volume applications

OPTION D – Let-Off Unit for Roll Goods on Infeed Table

- Designed for 3” cores, 48” diameter max, and 200 lb max. 300 lb design option available

- Simple hand wedge secures core to aluminum bar (shown)

- Manual friction brake prevents free wheeling of roll

OPTION E – Wind-Up Unit for Scrap or Finished Goods

- Rewind roll 35-40 lbs max, 48” max. Diameter

- Slip clutch design – standard 1/8 hp, heavy duty 1/3 hp

- Forward/reverse switch

- Quick disconnect plug into panel – 110v

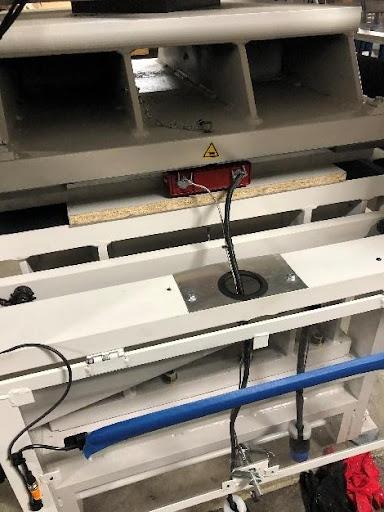

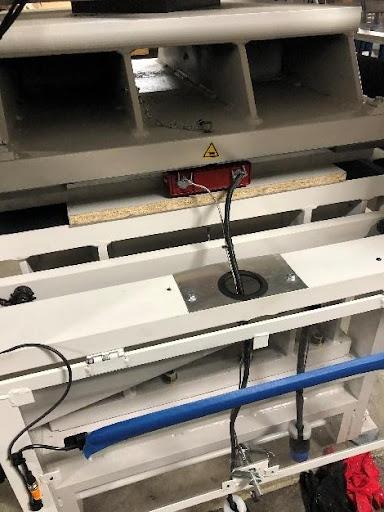

OPTION F/OPTION G – Color Photo Eye or Laser Sensor for Sheet/Plank Sensing

- Used for automated sensing and processing of sheets/planks

- Included in the standard design is a mechanical sensing wheel for plank front edge sensing. This is effective down to 1/16 – 1/8” material thickness depending on material stiffness

- The photo eye and laser are for thinner materials.

- Call us to discuss the pros/cons between photo eye/laser and application details between all three

OPTION H – Paper Storage Cart

- Easy cutting belt roll transportation and unwinding for belt replacement

- 38” max. width, 48” max. diameter, 900 lbs max. weight, 3” core

- Four heavy duty casters, two swivel, locking type

OPTION J – Heat Seal Design Upgrade

- Heat platen is design to mate with Ttarp’s standard die plate and slide in/out on the presses standard guide rails. Mounts on ram.

- Comes with fused heater control panel-box with digital heater control, power switch, T-couple, solid state relays, etc. 400 degrees F maximum.

- Power lead and T-couple are complete with male/female connectors for quick disconnect. In conjunction with die plate – rail mounting changeout is 10 minutes after cooling

- 6500w, 240v, 50amp - Note: smaller presses are 5000w

OPTION L – Left to Right Belt Feed Travel

- Application is about productivity by putting two (2) presses side by side with a single operator in the middle and have material flow be in the same direction

OPTION O – Press Upgrade from 45 to 55 tons

- Stand alone hydraulic pump package: 45 gpm, 20 hp/3ph/60hz/208-230/460v, Oil cooler

- 120 gallon tank with 25 gallon drip tray. 36”W x 48”L x 72”H

- Standard 7” to 8” hydraulic cylinder

OPTION P – Die Plate Exchanger

- Ergonomically safe single minute exchange of die

- Fits all 32" - 39" wide and 28" - 32" depth standard Ttarp press sizes

- Sturdy with horizontal and vertical die plate locking positions. Slotted registration plate for quick exchange of die

- See video

OPTION Q – Thicker Gauge Urethane Belt

- 1/8” thick urethane belt often used with serrated rule. Not meant for kiss cutting

- Servo motors and associated panel components increased in size

- Mechanical design upgrade changes include drive roller, idler rollers, belt tracker system, belt tensioning system, drive roller adjustment for belt replacement, etc.

.jpg?width=150&height=54&name=TTARP%20logo%20(1).jpg)